Today I introduce you

Two important roles in refrigeration system mechanics

Condenser and evaporator

Use easy-to-understand diagrams

Allows you to fully understand the treasures of the refrigeration family!

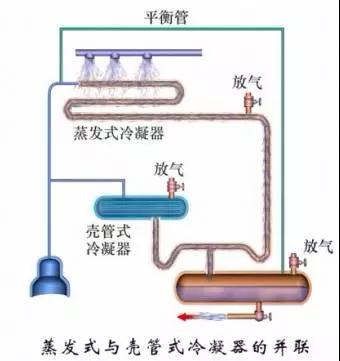

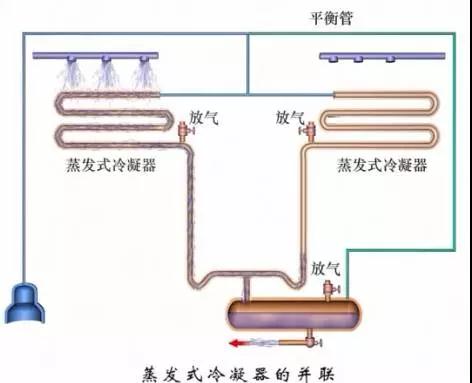

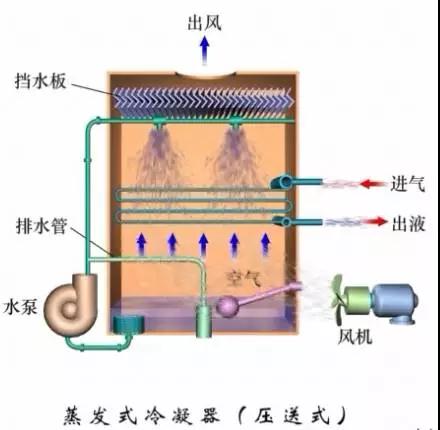

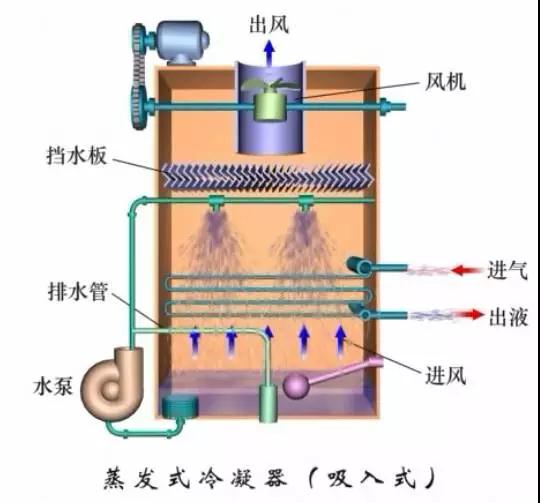

According to the cooling method, the condenser can be divided into an air-cooled condenser, a water-cooled condenser (a shell tube condenser, a tube condenser, a shell-coil condenser, a spiral plate condenser, and an immersed condenser) Evaporative and spray condensers.

1. Application object:

It is often used in refrigerators, freezers, small air conditioners, cold cars, car air conditioners and other small refrigeration devices.

Advantages: no water, simple installation, can be placed on the roof; heat transfer coefficient is small, affected by the ambient temperature, deterioration of the environment, dust difficult. Refrigeration Encyclopedia

Restriction: Only used in Freon refrigerators.

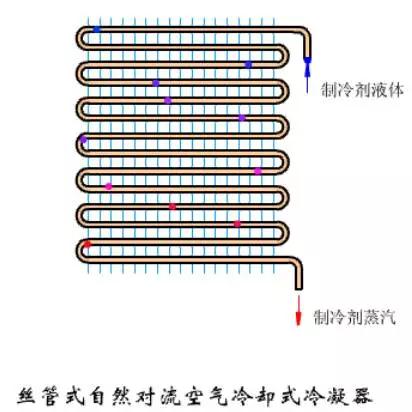

Classification: According to the flow of air, it can be divided into natural convection cooling condensers and forced convection cooling condensers.

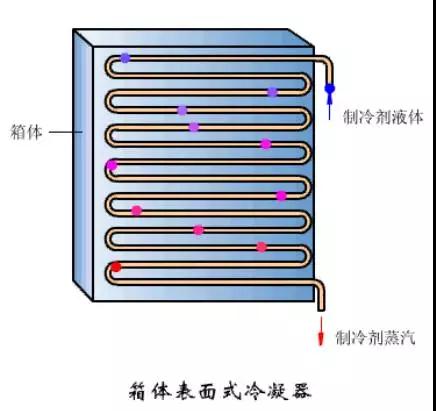

2. Natural convection cooling condenser

(1) Composition: Copper pipe (seamless steel pipe) and copper-plated steel wire.

(2) Features: No fan, saving power consumption, low noise, low heat transfer coefficient.

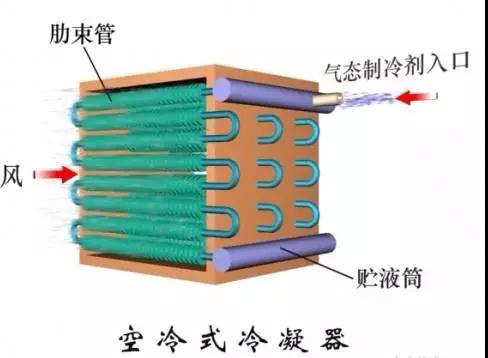

3. Forced convection cooling condenser

(1) Composition: Copper tubes (seamless steel tubes), fins, and axial fans.

(2) Principle

(3) Characteristics: The power consumption is large, the noise is large, and the heat transfer coefficient is high.

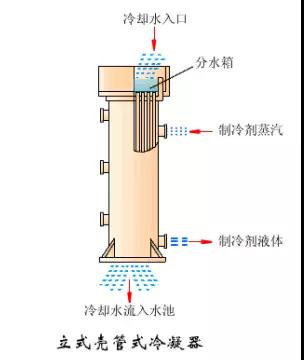

1. Shell-and-tube water-cooled condenser

Features: high heat transfer coefficient, small footprint, easy cleaning; large water consumption, bulky and bulky.

Suitable for: Large and medium-sized ammonia refrigeration systems. Refrigeration Encyclopedia.

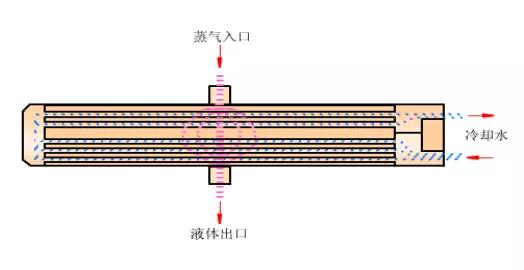

Horizontal shell and tube condenser:

Suitable for: Ammonia or Freon refrigeration systems

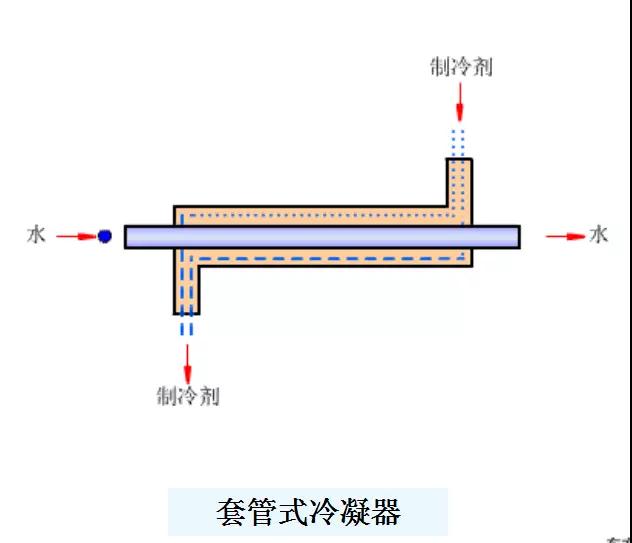

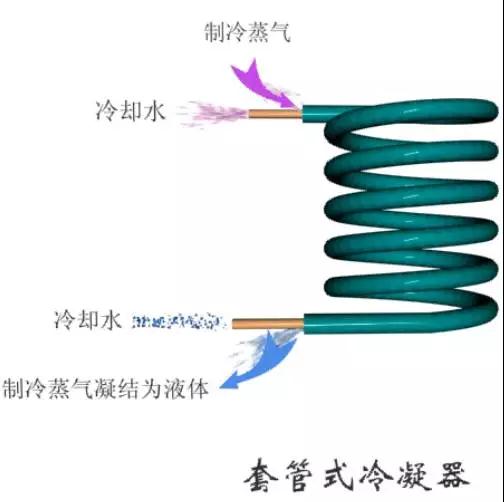

2. Sleeve condenser

Features: High heat transfer coefficient, small footprint, simple structure; large metal consumption, difficult cleaning, large water resistance.

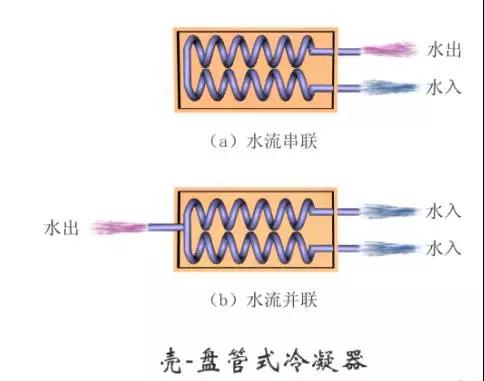

3.Shell - coil condenser

Features: Simple structure, no mechanical cleaning, strict water quality requirements, regular chemical cleaning.

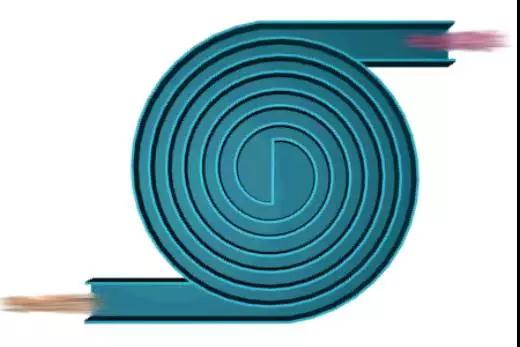

4. Spiral plate condenser

Features: small size, light weight, high heat transfer coefficient, but not suitable for high pressure, internal cleaning and maintenance is not easy, strict requirements on water quality. Refrigeration Encyclopedia.

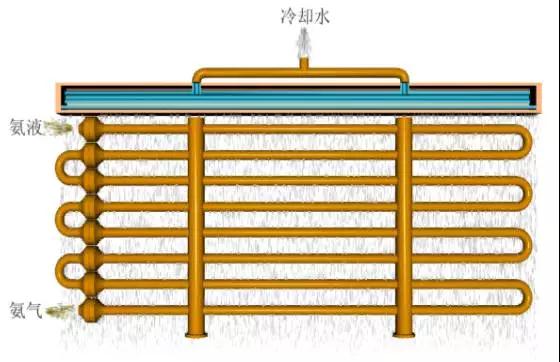

Features: Water saving, low cost, simple structure, easy to remove scale, small size

Features: simple structure, easy to use, easy to remove scale, low water quality requirements, but the metal consumption, large footprint, low heat transfer coefficient. Refrigeration Encyclopedia.

1. Role:

The refrigerant liquid vaporizes and absorbs the heat of the cooled medium in the evaporator to achieve the purpose of cooling.

2. Classification

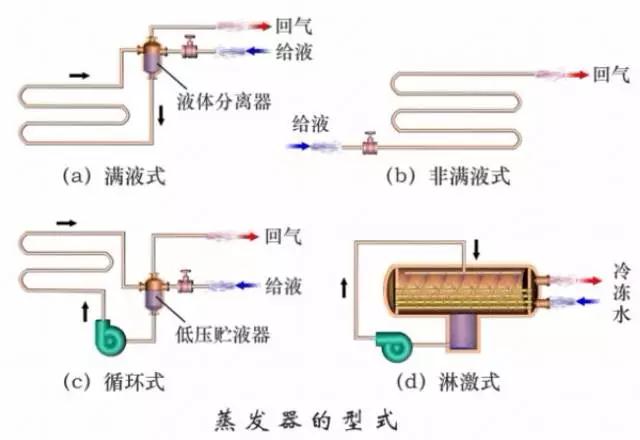

According to the full degree of evaporator and evaporation, it can be divided into four types:

Dry (non-liquid) evaporators, recirculating evaporators, flooded evaporators, spray evaporators.

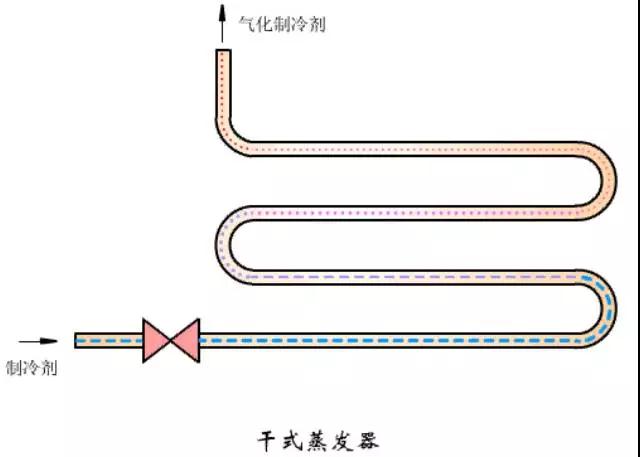

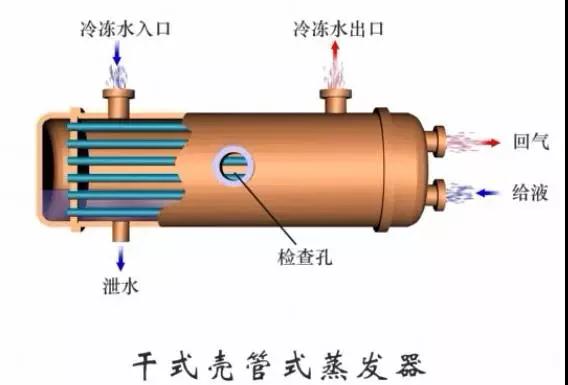

A dry evaporator

Refrigerant liquid A vaporizer that completely vaporizes inside the tube.

2. Work process:

3. Applicable objects:

Commonly used in cold storage or storage air conditioning.

4. Features of dry evaporator

(1) Advantages: Less liquid charge, no need for accumulators or need for small accumulators, easy to drain the lubricant from the evaporator back to the compressor, the loss of cold capacity is small, and the risk of freezing can be reduced.

(2) Disadvantages: Low heat transfer coefficient.

5. Classification:

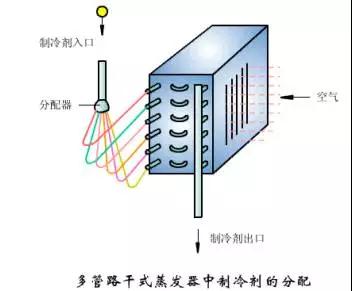

According to the different cooling objects, it can be divided into: cooling liquid type (U-tube type, straight tube type, plate type evaporator), cooling air type (smooth tube type, fin tube type). Refrigeration Encyclopedia.

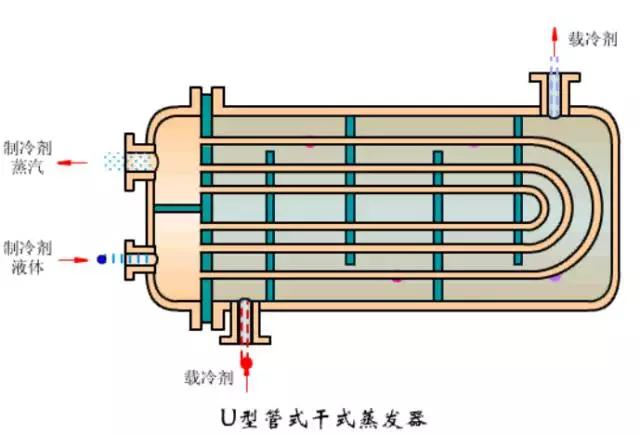

(1) U-tube dry evaporator

Advantages: The tube set can be pre-assembled, dirt can be removed outside the cleaning tube, heat stress can be eliminated, refrigerant distribution is even, and heat transfer effect is good.

Disadvantages: It is necessary to use different molds when manufacturing tube sets, and it is not possible to use longitudinal inner ribs. When the tube is damaged, it is not easy to replace. Refrigeration Encyclopedia.

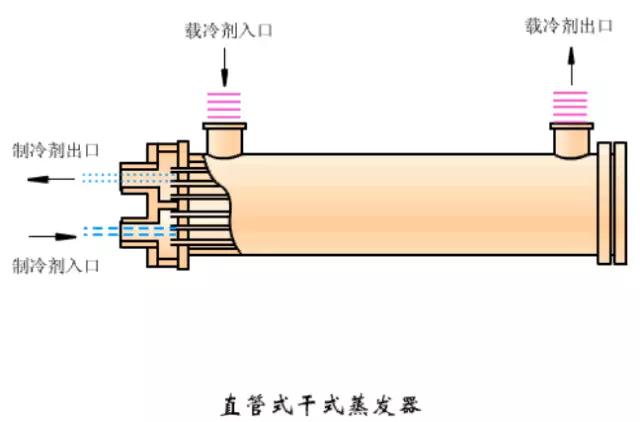

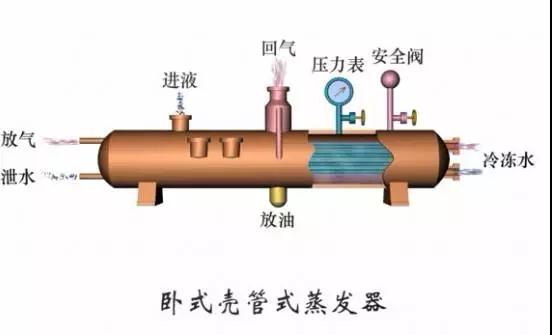

(2) Straight tube dry evaporator

Composition: shell, tube, baffle, end cap, tube sheet, etc.

In order to increase the heat transfer coefficient, the inner tube may be a smooth tube or a longitudinal inner fin tube, and generally no outer rib tube is used.

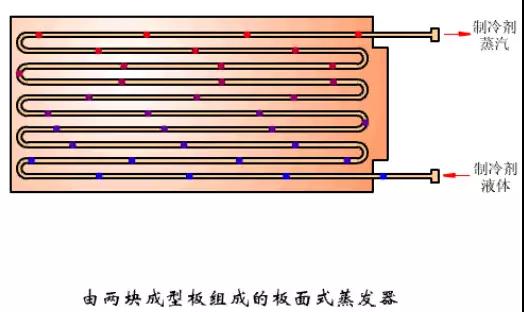

(3) Plate evaporator

Advantages: Small resistance, compact structure, low metal consumption, adjustable heat transfer area, etc.

Long press the QR code

Follow SUNNY-HVAC for more information

Shanghai SUNNY-HVAC Refrigeration Equipment Co., Ltd.!

Industrial refrigeration, civil air conditioning manufacturing experts