Chillers are the cooling equipment that must be used in summer, and many companies also need to operate 24 hours, so the utilization rate of chillers is very high. However, after entering autumn and winter, companies in some regions do not need chiller cooling, and only need to cool through cooling towers. Then, when the company disables the chiller, it is still necessary to do a good job of chiller maintenance to facilitate the normal operation of the chiller in the next year.

Below, Xiaobian explains how to properly maintain the chiller in autumn and winter:

Shutdown maintenance in autumn and winter

The first thing we need to do is:

1. Shut off the water source of the chiller, and clean the water inside the unit components and the pipeline to prevent the residual water after the shutdown from rusting the components of the unit, or that the temperature is too low to freeze-expand the copper pipe;

2. Turn off the power and check each part for wear (if any, replace it);

3. Clean the fan of the air-cooled chiller and keep it in a clean state;

4, there is water tank coil evaporator tank, to see if there are debris and other debris and give clearance;

5, through the data records to understand the use of lubricating oil, according to the use of standards to regularly replace the lubricating oil to maintain a good lubrication.

Second, the surface of the chiller is also very important. After the machine shuts down, clean the surface of the unit with a cleaning tool. After it is dry, cover the unit with a cloth or a gown to ensure that no dust or other debris will adhere to the unit. This will ensure that it will be dry when used in the coming year. Clean water chiller.

Objective: To do the above work when the unit is shut down, it can promptly find out where the chiller problem lies and eliminate, ensure the unit performance is stable, and it can be put into use safely and quickly in the coming year. Another benefit is that the life of the unit will be longer. Any machinery and equipment, only cherish, and its maintenance work to ensure performance and use of time, chillers are no exception.

Daily maintenance and inspection

1) Remove debris from installation and repair, and keep the environment of the equipment room and the surrounding area of the unit clean;

2) Remove dust and dirt that has been exposed on the pipeline so that leaks and repairs can be found in time;

3) Check whether the heat insulation material of the heat exchanger and pipe is in good condition. If it is found to be damaged or falling off, it shall be promptly repaired;

4) Check the fasteners of the unit for looseness, properly tighten the fasteners, eliminate vibration, and prevent leakage;

5) Check whether the line voltage of the unit power supply and the unbalance of each phase voltage are within the specified range;

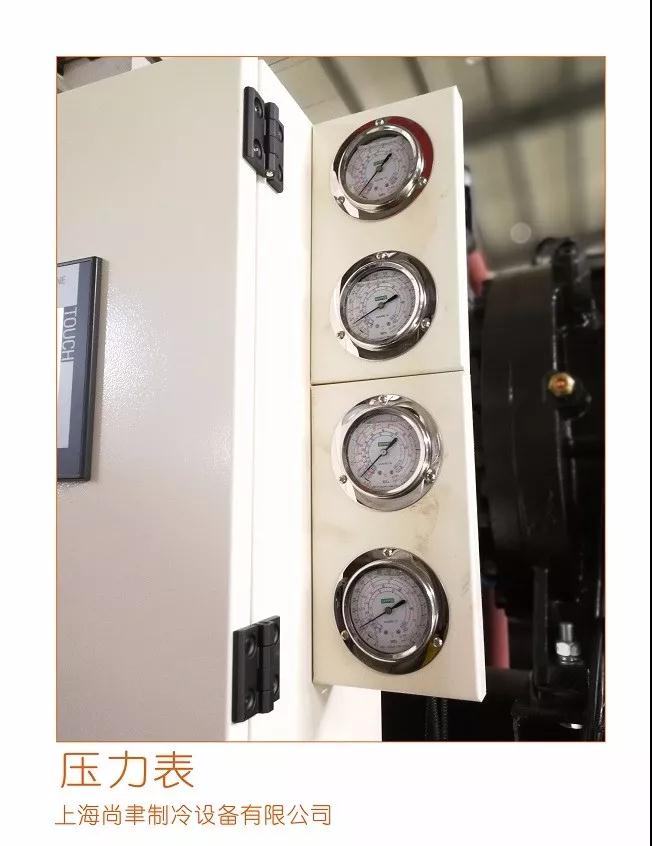

6) Record the unit's operating data: unit voltage, current, high and low pressure gauge pressure, frozen inlet and outlet water temperature, cooling water inlet and outlet water temperature, compressor discharge temperature, etc.;

7) Check whether the pressure indicated by the unit's high and low pressure gauges is normal;

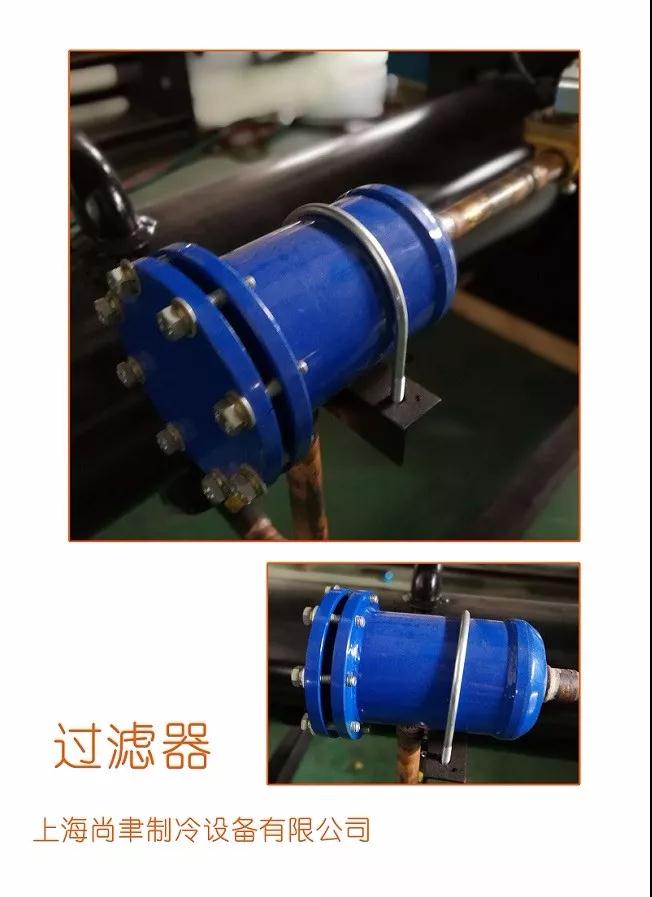

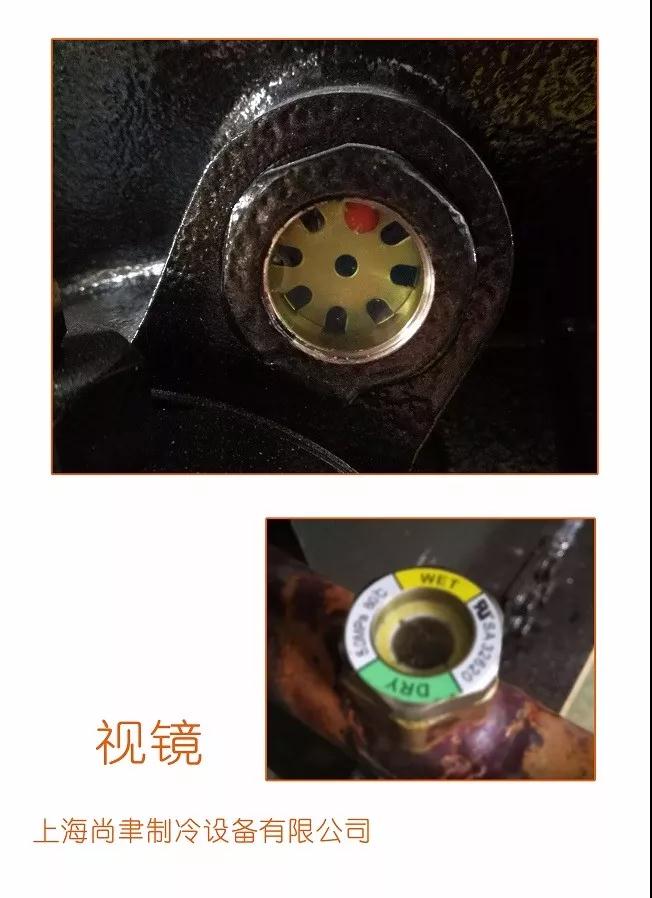

8) Check the dry filter. If a frosting phenomenon is found at this location, it indicates that the filter is blocked and the filter element needs to be replaced;

9) Check the moisture indicator of the sight glass. If it shows yellow, replace the dry filter element.

10) Apply grease to the valve stems of the valves of the equipment and place a few drops of oil on the door hinges and door locks of the control cabinet to avoid rusting and biting of moving parts.

11) Check whether the screws of each device are loose;

12) Check the leakage of each pipe joint;

13) Check if the wires are worn, the connection is firm, and whether the contacts are burned.

▲ Warning! ! In order to prevent injuries or death caused by electric shock or contact with moving parts, the isolation switch of the locking unit is in a disengaged state.

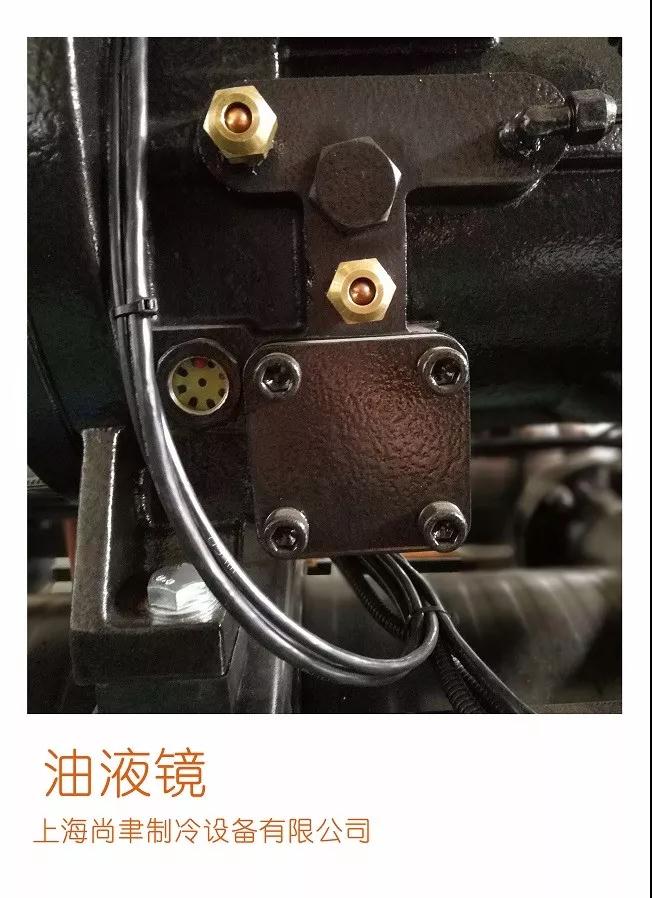

14) Check the compressor oil level is normal;

15) Inspect the freezing and cooling water system for seepage of air;

16) Check whether the refrigerant pressure is normal;

17) Clean the surface of the condenser;

18) Check whether the expansion tank and make-up water are normal;

19) Clean all the water filters of the freezing and cooling water system;

20) In the case of full load operation of the unit, check the temperature difference of the drying filter inlet and outlet sections.

21) Analyze the compressor oil in the laboratory to check the water content and acidity of the refrigerant system. When the PH value is lower than 6, the compressor oil must be replaced. If there is no condition for checking the acidity, the dry filter element of the refrigerant system should be replaced regularly to keep the system dry well;

22) Fasten all wire connectors in the control box and starter cabinet;

▲ Warning! ! In order to prevent injuries or death caused by electric shock or contact with moving parts, the isolation switch of the locking unit is in a disengaged state.

23) Detect refrigerant leakage at all connections;

24) Use non-destructive testing of the pipeline every three years to test the evaporator and condenser tube bundles;

▲Note: For the use of chillers, it may be better to shorten the cycle of these tube bundle inspections, especially for some important occasions.

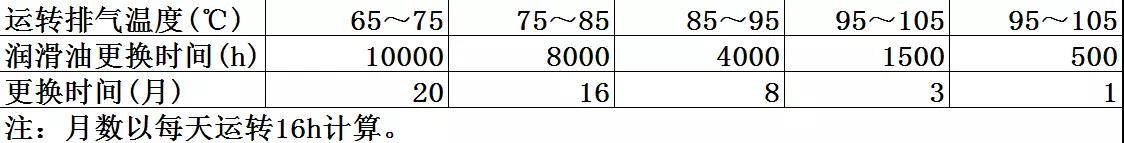

25) In general, check or replace the lubricant every 5000 to 10000 hours of operation. After the first operation, it is recommended to replace the lubricant between 2000 and 2500 hours and clean the oil filter and the compressor suction strainer. Since the residue of the system assembly will accumulate in the compressor after the official operation, it should be replaced after 2500 hours or 3 months, and then be replaced periodically according to the cleanliness of the system. If the system is clean, it can be every 10,000 hours ( Or change it once a year. If the exhaust temperature of the compressor is maintained at a high temperature for a long period of time, the deterioration rate of the lubricant is very fast. Check the deterioration period of the lubricant according to the cycle recommended in the table below.

▲Note: In the case where the compressor motor is burned out in the previous example, after replacing the compressor, the unit should be run for 24-48 hours and replaced with 1-3 times of refrigeration oil. The status or timing of the lubricating oil should be tracked every month (200 hours is recommended) Replace the oil until the system is clean, otherwise the compressor may burn again.

26) According to the application of the unit, contact the company or a suitable maintenance company to perform a comprehensive inspection at the appointed time.

Antifreeze precautions

When the winter temperature in the host room is lower than 0°C, freeze prevention measures shall be taken for the host, the chilled water pump and the cooling water pump.

(1) Host freezing protection: The main condenser, evaporator inlet and outlet valves are closed, the drain valve and the vent valve are opened, and the remaining water is blown clean with compressed air.

(2) Antifreeze of the pump: Close the inlet and outlet valves of the chilled water pump, open the pump drain valve and the vent valve, and place clean water. Open the valve at the lowest point of the cooling water system, release the cooling water, and open the water pump drain valve. After the system water is drained, to prevent rain water from entering the cooling tower, close the cooling tower outlet main valve and open the cooling tower drain pan drain valve. To drain rainwater from the drain valve in a timely manner.

In general, cooling tower make-up pipes are exposed outdoors, and most of them are insulated by antifreeze. However, in practice, freeze-ups often occur even if the insulation is used. In order to solve this problem, when the water supply pipe of the cooling tower is taken out from the room, a valve is added, and a drain valve is added at the lowest point of the water supply pipe. When the winter arrives, the valve in the room is closed and the lowest point of the drain valve is opened. The water in the outdoor pipe is exhausted, so that the pipeline does not need to be insulated and will not be cracked.

During the holidays, the ambient temperature is low, and parts of the water system may be below 0°C for a long time, which may result in freezing. The management personnel are required to turn on the water pump according to the actual situation and raise the temperature of the water in the system. Therefore, the management staff responds. The entire central air-conditioning system is fully aware of the situation, to identify the vulnerable areas, in advance to do preventive work to ensure that the water system is not frozen.

If the ambient temperature is lower than 0°C and the equipment is running, users are advised to add antifreeze in the cooling tower or water tank (adjust the concentration ratio of antifreeze according to the local environment).

About SUNNY

Shanghai Shangshang Refrigeration Equipment Co., Ltd. is a refrigeration equipment manufacturing, designing, researching, developing and managing "SUNNY" brand chiller, heat recovery unit, environmental protection chiller, laser chiller, cold oil machine, mold temperature chiller, and low temperature freezer. And as well as plant comfort central air-conditioning engineering, clean room workshops, refrigeration products needed for processing and manufacturing of ancillary products, refrigeration and air conditioning system design, manufacture, installation, maintenance, commissioning and technical services, etc.

The company has been continuously innovating in the system, mechanism, technology and management to achieve a successful road to joint ventures, cooperation, and economic growth, and achieved rapid development of the company.

Long press the QR code

Follow SUNNY-HVAC for more information

Shanghai SUNNY-HVAC Refrigeration Equipment Co., Ltd.!

Industrial refrigeration, civil air conditioning manufacturing experts